We’re The Metal Cutting Experts

If you need metal cutting in Peoria IL, SMF offers many options. Because every cutting job is different, we provide several different types of quality cutting technologies. Choose from laser cutting, saw cutting and plasma cutting – all have their individual advantages and disadvantages. Unsure which cutting option would work best for your project? Call SMS at 309-432-2586.

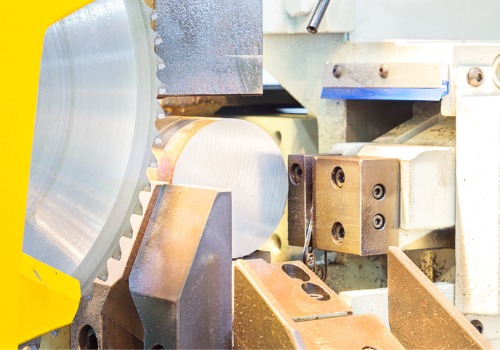

What To Know About Saw Cutting

Our 20” diameter saw can cut even large pieces of metal. It’s heavy-duty enough to handle entire bundles of pipes or tubing or even a stack of metal bars. Here are some considerations of saw cutting:

- Saws offer a faster turn-around than most other cutting methods: Of all our cutting processes, saw cutting is the quickest.

- The ability to cut a bundle of metals at once speeds things up considerably. It allows us to cut multiple pieces, such as stacks of metal bars or bundles of tubing, even faster.

- With automation, technology helps us complete all jobs with precision and consistency.

- Saw cutting offers a high degree of accuracy, but it is not as precise as laser cutting. However, it’s still appropriate for most jobs.

What To Know About Laser Cutting

At SMF, we have invested in some of the largest laser cutting machines in the country. Having these high-capacity laser cutters allows us to handle the largest jobs. Our biggest lasers have a cutting capacity of 54’ long and 12’ wide. Our ability to accommodate these larger pieces of metal means reduced setup time. It also allows us to complete more pieces in a shorter time. This efficiency saves you both time and money. A significant advantage of laser cutting is its precision: Laser cutting offers the most accurate cuts available from any existing technology. We use exact calculations and computerized measuring technology to achieve this accuracy. Here are some considerations of laser cutting:

- Accuracy: Computer-assisted setup allows our machines to offer the most precise and accurate cuts available from any technology that exists today. Each and every piece of metal will meet your exact specifications.

- Complexity: Cutting complex shapes is not a problem for our laser cutters.

- Reduced waste of metal and energy: The large size of our lasers allows us to maximize material usage, resulting in less wasted and scrap material.

- Automation: This allows us to save time and increase efficiency by running jobs in less time than any other method requires.

What To Know About Plasma Cutting

We’ve invested in 13’ by 12’ plasma cutting tables so we can burn your parts to the highest quality possible. Plasma arc cutting – the official name of plasma cutting – uses exceedingly high temperatures to cut through metals. Here are some things to know about plasma cutting:

- Even your thickest parts are no match for our plasma cutters. They can handle metals even thicker than a laser cutter can manage. In addition, our plasma cutter can divide sheets of metal, including carbon steel, stainless steel, aluminum, copper alloys and more. Our plasma cutter can get through metals up to 1.5 inches thick.

- Plasma cutting is far more affordable than laser cutting, although not quite as precise. This makes it ideal for jobs that do not require as much precision as laser cutting. Plasma cutting offers real savings on such projects.

- In some cases, such as cutting reflecting metal, plasma cutting is safer and preferable.

Are You Ready To Work With Us?

At SMF, we offer a full range of metal fabrication services and want to be your one-stop metal shop. Call us today at 309-432-2586. Headquartered in Illinois with another campus in South Carolina, we perform metal cutting in Peoria IL and throughout the United States.