Are you in the market for a one-stop metal shop capable of handling all your metal cutting needs? SMF has the equipment and expertise to provide the options you need. If you need metal cutting in Rock Hill SC, call SMF at 864-226-0470.

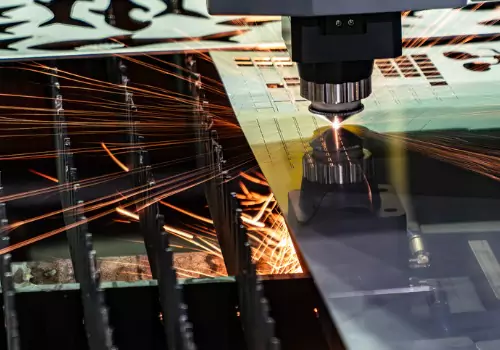

Metal cutting is a fundamental process in manufacturing, with laser, plasma and saw cutting being among the most commonly used methods. Each technique offers unique advantages and disadvantages that make them suitable for different applications.

The advantages of laser cutting include:

Laser cutting machines are expensive, and operational costs can be high due to energy consumption. It’s less effective on thicker materials, as the laser’s efficiency decreases with thickness. While precise, laser cutting can be slower compared to plasma cutting for thicker materials.

The advantages of plasma cutting include:

While accurate, plasma cutting is less precise than laser cutting, making it less suitable for highly detailed work. In addition, cuts may require additional finishing due to rougher edges and dross formation.

The advantages of saw cutting include:

Saw cutting is slower compared to laser and plasma cutting, especially on thicker materials. It is less precise, which may not be suitable for highly detailed or complex cuts.

Choosing the right metal cutting method depends on specific project requirements, including precision, material type, thickness and budget. Understanding the pros and cons of laser, plasma, and saw cutting helps in selecting the best technique for optimal results. If you’re unsure which manufacturing options are right for your project, we’re here to help you decide. If you need metal cutting in Rock Hill SC, give us a call. To reach us in South Carolina, call 864-226-0470.